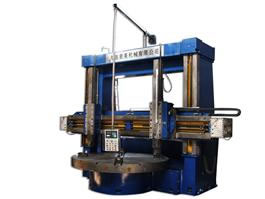

Dalian Yimei machinery Co., Ltd

Features of Vertical Turning Lathe with Double Column

1. With the adoption of modern advanced technology, our machine integrates mechanic, electric and hydraulic technologies as a whole unit.Parameters of China Double Column Lathe Machine

|

Term

|

Unit

|

CK5280

|

|

Max. turning diameter

|

mm

|

8000

|

|

Worktable diameter

|

mm

|

6000/7200

|

|

Max. height of work piece

|

mm

|

4000/4500

|

|

Max. weight of workpiece

|

t.

|

150/250

|

|

Max. cutting force of right tool post

|

KN

|

120

|

|

Max. cutting force of left tool post

|

KN

|

100

|

|

Max. total cutting force

|

KN

|

220

|

|

Max. torque of worktable

|

KN

|

200/400

|

|

Stage number of variable speed of

worktable

|

Two gears

|

|

|

Variable speed range of worktable

|

r/min

|

0.2-20/0.1-16

|

|

Feeding stage number

|

AV servo stepless

|

|

|

Feeding range

|

mm/min

|

0.1-2000

|

|

Horizontal travel of tool post

|

mm

|

4350

|

|

Vertical travel of tool post

|

mm

|

1600/2000/2500

|

|

Crossbeam moving speed

|

mm/min

|

380

|

|

Tool post rapid moving speed

|

mm/min

|

4000

|

|

Max. swivel angle of worktable

|

。

|

+30

|

|

Positioning accuracy

|

mm

|

0.03

|

|

Repeatability positioning accuracy

|

mm

|

0.015

|

|

Machining accuracy

|

IT7

|

|

|

Main electric motor power

|

KW

|

DC110/132

|

|

Overall size

|

mm

|

1000×15000×8925

|

|

Weight of worktable

|

t.

|

270

|

Tag: Double Column Vertical Lathe, | China Double Column Turning Lathe | Chinese Double Column Vertical Lathe

Tag: Double Column Turning and Milling Center | China Turning and Milling Compound Center | Double Column Milling and Turning Center