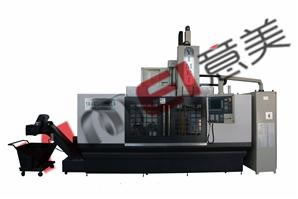

Dalian Yimei machinery Co., Ltd

Features:

1. Motion guide ways all adopt hydrostatic guide ways.Parameters:

|

Term

|

Unit

|

CK5228

|

|

Max. turning diameter

|

mm

|

2900

|

|

Worktable diameter

|

mm

|

2250

|

|

Max. height of work piece

|

mm

|

2000/2500

|

|

Max. weight of work piece

|

t.

|

16

|

|

Max. cutting force of right tool post

|

KN

|

35

|

|

Max. cutting force of left tool post

|

KN

|

30

|

|

Max. torque of worktable

|

KN

|

63

|

|

Stage number of variable speed of worktable

|

Four gears+stepless

|

|

|

Variable speed range of worktable

|

r/min

|

0.5-63

|

|

Feeding range

|

mm/min

|

0.1-2000

|

|

Horizontal travel of tool post

|

mm

|

1600

|

|

Vertical travel of tool post

|

mm

|

1000/1250

|

|

Crossbeam moving speed

|

mm/min

|

350

|

|

Tool post rapid moving speed

|

mm/min

|

6000

|

|

Max. swivel angle of worktable

|

。

|

+/-30

|

|

Positioning accuracy

|

mm

|

0.03

|

|

Repeatability positioning accuracy

|

mm

|

0.015

|

|

Machining accuracy

|

IT7

|

|

|

Main electric motor power

|

KW

|

55

|

|

Guide way type of worktable

|

mm

|

Hydraulic/static pressure

|

|

Weight of worktable

|

t.

|

35/36

|

Tag: Economic Single Column Lathe | Small Vertical lathe | Economic Column Lath

Tag: Numerical Control Vertical Lathe | Professional Type Vertical Lathe Machine | China Single Column Vertical Lathe